Ignition Discover Gallery

2025 Project

CanDoIt Solutions

Project For: Vide Ultra

Enterprise Ignition System Transforms Operations For One Of Australia's Largest Fruit Producers

Project Overview

In the highly competitive agricultural sector, innovation, real-time visibility, and operational efficiency are no longer optional — they are essential for survival. Vide Ultra, supporting various Australian fruit companies, recognized this need for their customer as they expanded their orchard, cold storage, and processing operations across Australia.

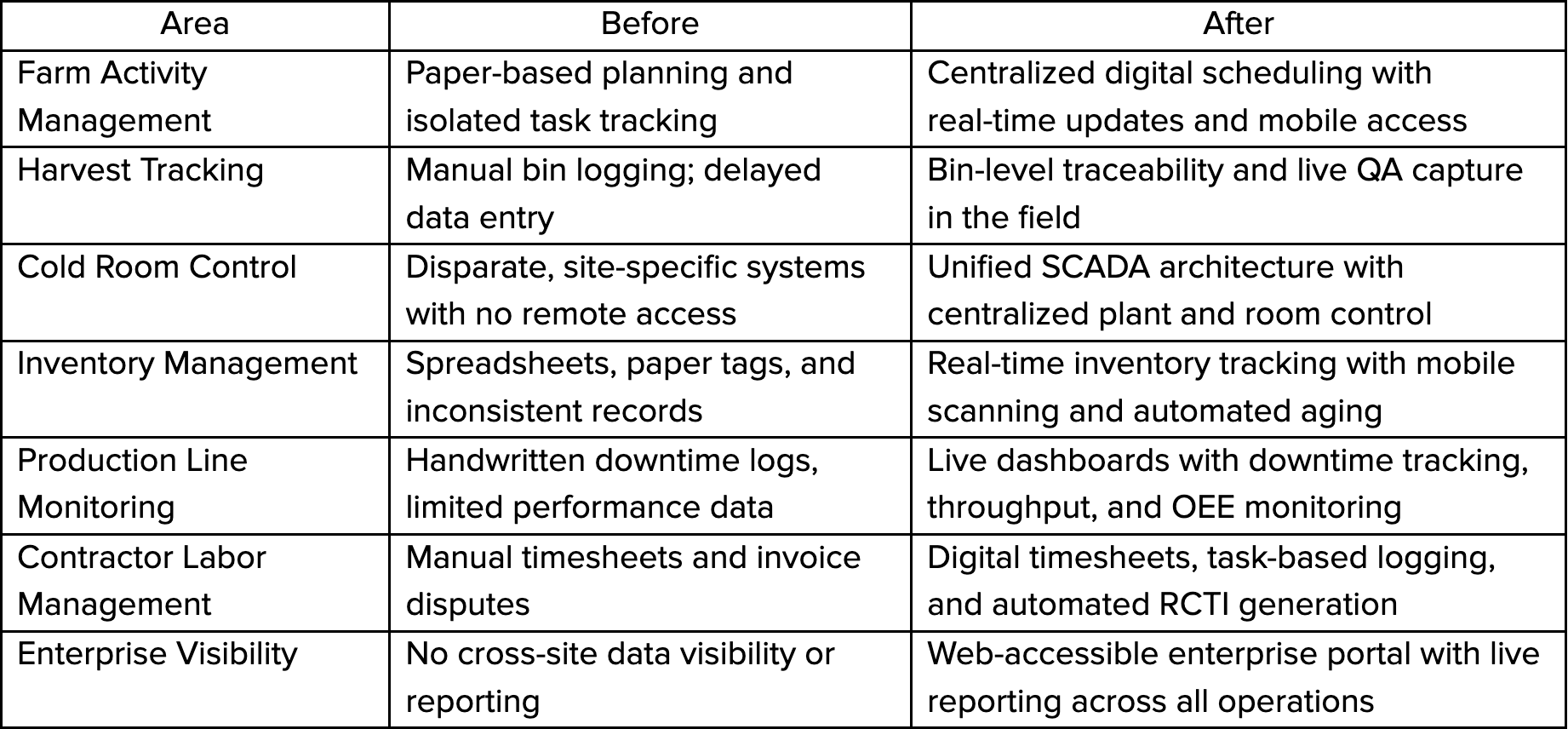

Following years of growth through a combination of greenfield developments and strategic acquisitions, the client’s operational technology environment had become fragmented, inefficient, and increasingly difficult to scale. Manual processes, siloed systems, and a mixture of outdated HMI and SCADA architectures created significant barriers to achieving operational excellence, quality control, and enterprise-wide visibility.

Recognizing the urgent need for modernization, Vide Ultra brought in CanDoIt Solutions to design and deliver a fully integrated operational technology platform. Built on Inductive Automation’s Ignition ecosystem, alongside complementary technologies, the solution was crafted to unify operations from orchard management through to cold storage and high-volume processing.

By centralizing data flows across all business layers, CanDoIt Solutions empowered Vide Ultra with a resilient, scalable architecture that delivers:

- Real-time operational visibility

- Full end-to-end traceability

- Performance optimization

- Data-driven strategic decision-making across the entire enterprise

Ignition’s flexibility, rapid development capabilities, and modular approach allowed CanDoIt Solutions to bridge gaps between traditionally siloed operations, creating a future-ready foundation for continued growth and innovation in a highly competitive agricultural market.

Challenges

Vide Ultra faced systemic challenges across its vertically integrated agricultural business at the farm, storage, and processing levels spanning:

- 22 orchards

- 5 cold storage sites (76 rooms)

- 2 major fruit processing facilities (9 production lines and 3 high-bay storage systems)

- 90 PLCs; 80,000 Tags (30+ pumpsheds in future)

- 60+ sessions and devices

Farm challenges:

- Reliance on paper records, Excel spreadsheets, and undocumented knowledge for farm operations.

- Lack of centralized reporting for yield data, irrigation, fertigation, and material inputs.

- No visibility over seasonal labor productivity.

- No predictive material or harvest planning.

- Poor or inconsistent in-field QA practices.

Storage facility challenges:

- Fragmented, legacy cold room control systems with no unified standard.

- Multiple, often unreliable temperature sensors and loggers.

- Manual, paper-based inventory tracking leading to misplaced bins and lost stock.

- No real-time environmental control or alarming — operators relied on "feel" rather than live data.

Processing facility challenges:

- Three different stock management systems, which created inventory conflicts.

- Manual receipting into grading and packing lines.

- No live performance tracking or downtime reporting on production lines.

- No ability to trace product quality from farm to market.

The technical and operational challenges proved substantial as well. CanDoIt needed to:

- Normalize inconsistent enterprise naming, systems, and historical farm data.

- Replace or integrate multiple incompatible cold store control systems.

- Deliver a functional system within a tight six-month pre-harvest window with a small team.

- Enable seasonal worker onboarding, flexible credentialing, and multi-language UI support.

- Bridge the legacy SCADA systems, which lacked modern APIs, into a unified Ignition architecture.

Solution

Delivering an integrated, enterprise-wide digital platform for an industry as complex as agriculture required a toolkit that could keep up — and scale far beyond. Ignition wasn’t just the right platform for this project: it was the only one that could have delivered it in time, within budget, and to the depth of functionality needed. Ignition’s unique combination of modularity, unlimited licensing, cross-platform design, and developer-first architecture allowed CanDoIt Solutions to move fast, integrate deeply, and build confidently across farms, facilities, and remote locations.

The web-based, mobile-ready Ignition Perspective Module eliminated the need for costly third-party UI frameworks while Ignition’s native MQTT and Edge support made integration with existing control systems seamless, regardless of age or vendor. And perhaps most importantly, its open architecture gave CanDoIt the freedom to solve problems their own way without compromise.

Hosted centrally but accessible from anywhere, the core Ignition Gateway is the beating heart of the Vide Ultra operational platform. The system features the following key modules:

- Perspective Module - Powers all user interfaces across desktop, mobile, and tablet from orchard task management to enterprise dashboards.

- Alarm Notification Module - Integrated with Twilio SMS and email for proactive alerts on refrigeration faults, room temperature deviations, equipment downtime, and more.

- Tag Historian Module - Captures real-time process, refrigeration, quality, and traceability data — optimized for high-volume cold storage environments.

- Reporting Module - Automatically generates daily performance summaries, spray diaries, inventory snapshots, and compliance logs across all operations.

- Sepasoft Track & Trace Module - Delivers true end-to-end product genealogy, linking orchard block, harvest bin, storage room, and final processed product into a single, queryable chain.

- Identity Provider (IdP) Integration (ENTRA) - Enables secure single sign-on (SSO) and fine-grained, role-based access control for staff, contractors, and management.

With Ignition Edge, Vide Ulta gained resilience, standardization, and real-time control as well as SCADA-level visibility to four remote cold storage facilities that previously had none, all without needing a full local install. These Edge Gateways made use of:

- MQTT Transmission & Store and Forward - Ensures cold store data is never lost, even during network outages — a critical feature in regional Australia.

- Local Edge Historians - Provide local buffering and process history, allowing real-time refrigeration analytics and alarm response, even when offline.

Although full Ignition mobile offline support (via Perspective Workstation) wasn’t available at project launch, the platform was designed from day one to support mobile-first workflows.

- Over 40 ruggedized mobile devices - Run Power Apps integrated with Ignition via Azure services, enabling orchard workers to capture data in the field from harvest QA to bin tagging.

- Azure Power Platform integration - Ensures offline-first operation and automatic data sync once network is restored.

- Migration Path to Ignition 8.3 - As soon as 8.3 offline capabilities are released, the existing workflows are ready to be migrated directly into Ignition — further consolidating the ecosystem.

To support enterprise visibility, analytics, and archival data, CanDoIt integrated Ignition with Vide Ultra’s cloud services infrastructure:

- Azure SQL database - Stores long-term archival data across farming, refrigeration, and processing — optimized for business intelligence and compliance.

- Future-ready by design - The architecture is prepared for AI integrations, satellite-based orchard performance analytics, and predictive cold room optimization models.

At the heart of Vide Ultra’s operation are the orchards, which make up thousands of hectares of fruit trees across 22 sites. Managing these assets efficiently, while ensuring compliance and maximizing yield, is vital for profitability and product quality.

Before the transformation, orchard operations were managed through a fragmented approach that limited their ability to optimize farm operations, enforce compliance standards (especially for spray diaries), or analyze historical performance trends across blocks or varieties.

Using Perspective, CanDoIt Solutions delivered a comprehensive Orchard Management Application (OMA): a digital platform designed specifically for large-scale, multi-orchard operations. The OMA centralized all aspects of orchard activity management into a live, dynamic, and mobile-enabled system.

The key features of the OMA are:

- Activity planning across seasons (pruning, slashing, spraying, harvesting, irrigation, fertigation).

- Task assignment to blocks, workers, or contractors.

- Real-time labor tracking; sign in/out.

- Receipt Created Tax Invoices (RCTI).

- Real-time task completion tracking.

- Re-scheduling based on weather events or operational delays.

Seasonal labor is essential to large-scale horticultural operations, but managing contractor hours, task assignment, compliance, and cost tracking had traditionally been a manual and error-prone process. This lack of visibility made it difficult to forecast workforce requirements, validate invoices, or understand true operational efficiency.

Using Ignition Perspective and Power Apps integrations, CanDoIt Solutions developed a real-time workforce management solution tailored to the agriculture industry’s seasonal operations, digitally capturing all contractor and staff activity and enabling:

- Assignment of work to blocks and activity types.

- Live clock-in/clock-out logging (via mobile or kiosk).

- Labor hour tracking per block, per task, per worker or contractor.

- Real-time task completion updates.

- Accurate contractor cost reporting with full traceability.

To support compliance and simplify contractor payments, the system also includes automated RCTI (Recipient-Created Tax Invoice) generation.

As labor data is captured and verified:

- The system automatically generates RCTIs based on approved hours and pre-agreed rates.

- Invoices can be reviewed and exported for payment with full audit trails.

- All calculations are tied back to orchard blocks, task types, and contractors.

- The system eliminates the risk of invoicing disputes or mismatched records.

Managers can access real-time dashboards summarizing completed activities, active tasks, resource usage, and projected labor needs across all orchards. This live overview enables Vide Ultra to identify underperforming blocks early, better align resource allocation, and forecast harvest and input requirements months ahead via performance KPIs, activity completion rates, blocked labor hours and predictive planning based on historical trends.

Chemical application compliance (for domestic food safety and international export regulations) is critical for both modern agriculture as well as safety of staff working in the field. Prior to modernization, Vide Ultra manually logged spray records, risking errors or non-compliance. Through the OMA, the system automatically generates spray sheets based on planned chemical applications.

Harvesting is a critical, time-sensitive operation. With the Orchard Management Platform, Vide Ultra captures real-time harvest data at the bin level, which is linked directly to orchard blocks, workers, and quality assurance results. Harvest data automatically updates central dashboards, feeding into cold store allocation and processing schedules.

Cold storage is one of the most critical — and complex — parts of agricultural operation. With over 70 individual cold rooms spread across five sites and seven distinct refrigeration plants, ensuring optimal climate control, energy efficiency, and product traceability was a major operational challenge. Before this project, each cold store operated as an isolated island.

Room controllers, refrigeration plants, and temperature sensors had been installed at different times using different vendors, resulting in:

- Multiple control philosophies

- No centralized visibility

- No remote access or consistent alarming

- No ability to track how long fruit had been in a room or its climate history

Worse still, operators made decisions on storage conditions — such as when to change temperature setpoints, defrost cycles, or move stock — based on intuition, not real-time data.

Using Ignition Edge Gateways installed at each cold store site, CanDoIt created a unified cold store control system. Each gateway communicates via MQTT with the central Ignition server, enabling secure, real-time data flow between refrigeration hardware, room sensors, and business systems, even across different vendors and protocols.

This architecture:

- Standardized control logic across all cold stores

- Allowed room and plant control to be managed centrally or remotely

- Made it possible to compare room performance across sites

- Enabled live alerting and remote troubleshooting

Perspective views allow Vide Ultra to proactively manage room conditions to match the specific needs of each fruit variety and destination market. Each of the 76 cold rooms now has its own Perspective view showing:

- Temperature, humidity, and oxygen levels (where applicable)

- Current stock count and storage duration

- DCA (Dynamic Controlled Atmosphere) parameters and setpoints

- Door open status, alarms, and recent actions

In addition to environmental control, Ignition tracks all bins and pallets stored within each cold room, updated in real time as product is moved in or out. Previously, the clients managed inventory with paper tags, clipboards, and Excel files. These often got damaged, went missing, or were months out of date. With Ignition, QR code scanning and room-based logic ensure that every bin in cold storage is known, timestamped, and traceable.

Fruit processing is the final critical stage before products reach customers. Efficiency, quality, and traceability at this point are vital not only for operational success but for maintaining brand reputation across domestic and export markets.

Prior to the transformation, the processing plants lacked live data, meaning that clients often operated reactively rather than proactively, slowing down problem resolution, reducing efficiency, and risking product inconsistencies.

With Ignition, processing plants have:

- Live dashboards showing production throughput and line speeds

- Automated downtime event capture with categorization and timestamps

- Yield tracking across every line and shift

- Direct links between product flow and original orchard harvest data (via Track & Trace)

- Supervisor and operator access from mobile devices and desktop terminals

Operators and supervisors can immediately spot issues — whether a line slowdown, a sudden drop in throughput, or an unexpected quality deviation — and take corrective action in real time.

Beyond day-to-day operations, the processing platform feeds key metrics directly into client enterprise reporting. By moving from manual records to real-time OEE tracking, Vide Ultra achieved a major leap in production visibility, efficiency, and decision-making quality.

One of Vide Ultra’s biggest challenges before this project was lack of cohesive operational visibility, siloing information into isolated systems. The clients needed a unified platform that could present live, accurate operational data from orchard to cold store to processing floor in a single enterprise view.

CanDoIt Solutions designed and built Agronomi.ai — a custom Perspective-based enterprise portal that consolidates operational reporting, live dashboards, and inventory management into a secure, web-accessible system.

Agronomi.ai acts as the central nervous system for client’s entire agricultural operation:

- Aggregating data from all farm, cold store, and processing systems via Ignition

- Providing mobile-ready, responsive dashboards

- Enforcing secure, role-based access across departments and management layers

Whether in the office, onsite at a farm, or traveling between facilities, executives and site managers can access:

- Harvest progress across all orchards

- Current inventory statuses across cold stores and high-bay storage

- Production throughput and downtime reporting from processing lines

- Active alarms and plant statuses from cold rooms

- Daily and seasonal operational KPIs

- Historical reports for compliance, planning, and trend analysis

Ignition and Agronomi.ai have turned the silos from a group of independently operating sites into a single, digitally connected agricultural enterprise capable of competing on both quality and efficiency in domestic and international markets.

Results:

Vide Ultra’s Digital Transformation solution delivered real-world results:

By digitizing and centralizing orchard operations in Ignition, Vide Ultra achieved:

- Operational Efficiency - Faster planning, better labor coordination, immediate operational oversight.

- Compliance Assurance - Fully traceable, digitally recorded chemical application and food safety data is audit-ready.

- Real-Time Decision-Making - Real-time response to weather changes, staff shortages, or pest outbreaks.

- Historical Data Analysis - Activity, yield, and performance trends can now guide agronomic decisions.

- Enhanced Yield & Quality - Optimized spray schedules, irrigation plans, and labor deployment have directly improved fruit quality and harvest yields.

The cold store platform, powered by Ignition and MQTT, delivered:

- Standardized Control - All cold rooms now follow a consistent logic, regardless of site or controller type

- Remote Oversight - Supervisors can monitor and adjust room conditions without being on-site

- Improved Product Quality - Dynamic cooling and DCA control based on fruit type and condition extends shelf life and export readiness

- Inventory Accuracy - No more lost bins: every item is traceable, timestamped, and accountable

- Energy Savings - Better climate management and plant visibility reduced overcooling and inefficiency

The real-time processing system delivered:

- Production Visibility - Instant awareness of line performance, downtime, and production output

- Operational Efficiency - Reduced unplanned downtime and faster issue response

- Product Quality Assurance: Early warning of potential quality issues before fruit reaches packing

- Data-Driven Decision-Making - Supervisors and executives now have the data they need to improve operations, scheduling, and investments

- Full Traceability - Processing data is linked back to orchard harvest data, completing the full track & trace loop

By consolidating all operational data into Agronomi.ai, Vide Ultra achieved a dramatic improvement in decision-making capabilities:

- Faster Response Times - Immediate visibility for issues in the orchard, cold store, or processing floor.

- Operational Alignment - Synchronized farm activities, storage operations, and processing plans across departments.

- Data-Driven Strategy - Seasonal planning, resource allocation, and market strategies based on live, empirical data rather than guesswork.

- Scalability - As Vide Ultra continues to expand, Agronomi.ai can seamlessly onboard new sites, orchards, or processing lines into the unified operational view.

Measurable Improvements:

- 80% reduction in manual data entry errors.

- 20% improvement in cold store energy consumption.

- 95% reduction in lost/misplaced bins.

- End-to-end product traceability from orchard to market.

- Real-time operational reporting across all business units.

Project Team

CanDoIt Solutions:

- Andrew H. Brown — Director & Lead Solution Architect

- Rhys Davies — Control Systems Engineer (Farm Operations & Mobile Integration)

- Jarrod Franz — Control Systems Engineer (Cold Store & Processing)

Vide Ultra:

- Andrew L. Brown — Head of Operational Technology

Start Date: October 2024

Deploy Date: March 2025

Project Scope:

Tags: 85,000

Screens: 100+

Clients: 40+ Mobile Scanners (Perspective app); 20+ Desktops

Alarms: 1,000s (UDTs, of course)

Devices used: 90+ PLCs, LoRaWan, Allen-Bradley (PLC5, SLC, Compact, Control), Omron (NX), Elliwel, Siemens (S7)

Architectures used: Hub & Spoke, Edge and central

Databases used: 6 DBs, MSSQL, POSTGRESS, MySQL

Historical data logged: ~10,000; full MES traceability for over 80,000 bins

Number of people on team: 2-3

Ignition Ecosystem: Cirrus Link, Sepasoft

Presented By:

Andrew Brown

Andrew Brown is the Director of CanDoIt Solutions, based in Brisbane, Australia. An active user and advocate of Ignition since 2014, Andrew has designed and delivered solutions ranging from highly customized applications to full enterprise-scale platforms — all built within the Ignition ecosystem. With a focus on practical innovation and real-world operational improvement, he has helped Australian businesses transform their operations, optimize performance, and achieve long-term scalability through modern industrial technology.

Created By:

CanDoIt Solutions

CanDoIt Solutions supports Australian industry by delivering end-to-end electrical and automation services, with a specialist focus on SCADA and MES systems. CanDoIt takes complex client needs and operational realities and transforms them into functional, scalable, and future-ready solutions. By bridging technology and operations, they enable their clients to focus on what they do best — producing world-class goods for both domestic and international markets.

Website: https://candoitsolutions.com.au/

Project For:

Vide Ultra

Vide Ultra is the operational technology arm of an agriculture investment group, one of Australia's largest fruit producers, managing 22 orchards, five cold stores, and two major processing facilities. Vide Ultra leads client Digital Transformation initiatives, delivering integrated SCADA, MES, and enterprise solutions to enhance traceability, efficiency, and operational performance across the supply chain.

Website: https://agronomi.ai/

Industry:

Agriculture